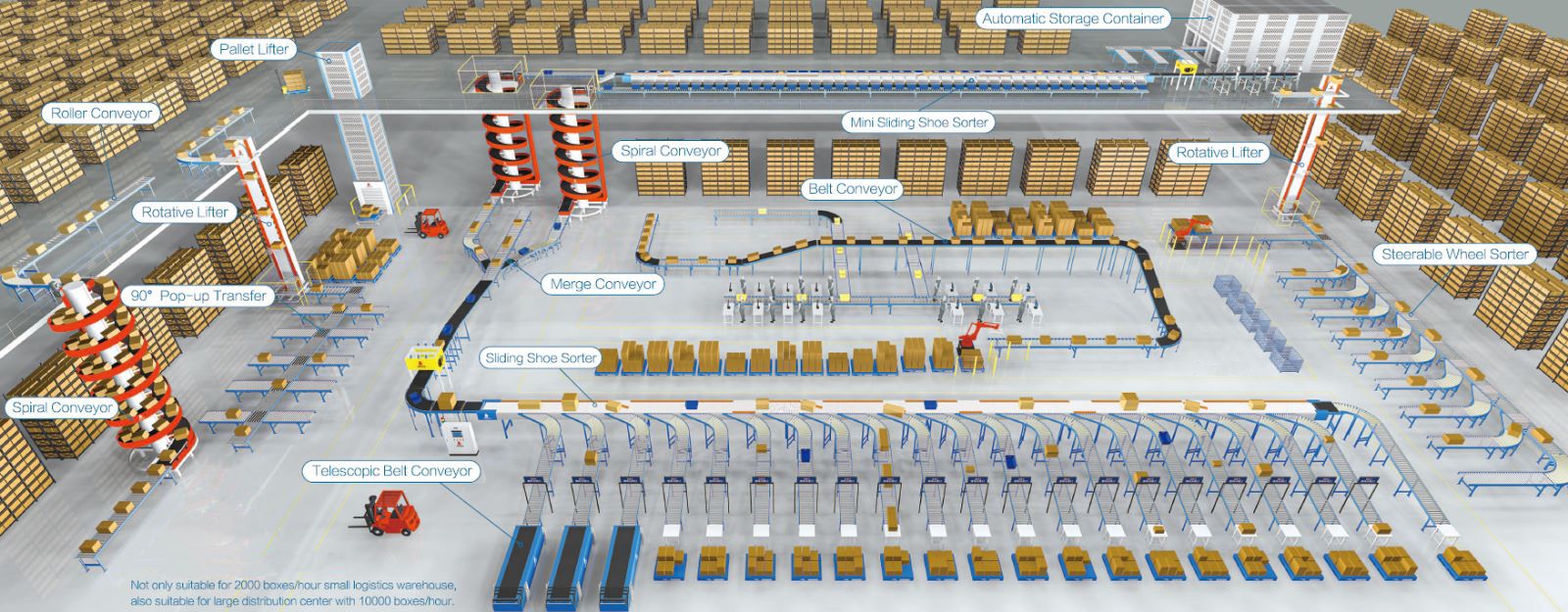

Sorter System

Sorting systems are used to classify products depending on their destinations in warehouses and distribution hubs. Random item flows are combined for shipment (outbound) or storage (inbound or returns). Sorting parameters are dependent on the kind of supply chain firm or application.

The common parts of a sorter system –

- A feeder system whose sole purpose to feed the products into the sorter in proper orientation and with proper spacing.

- Receptacles function is to receive the products as they leave the sorter towards a proper destination.

Benefits

- Implementing sorting technology can significantly reduce the risk of contamination from aflatoxins and foreign material, driving up food safety on the production line and offering a smart investment for processors and manufacturers.

- Improved order precision and increased order volume without commensurate increases in labor.

- Fewer damaged or defect products.

- Opportunity of regaining vertical space that is underutilized (depending on model).

There is a number of typical sorter designs:

1. Cross belt sorter

- In logistics, a cross belt sorter is a type of conveyor-based sortation system. It consists of a chain of independently operated short conveyor belts mounted transversely along the main track.

2. Paddle and pusher sorter

- Paddle sorters and pusher sorters are good for low to medium-throughput options for sorting irregularly shaped, difficult-to-convey items, and small items like polybags, cosmetics, or pharmaceuticals.

- These sorters have been in use for decades and have a long history of reliable & accurate performance.

3. Shoe Sorter

- On a shoe sorter conveyor system, products are transported on aluminum slats.

- Divert shoes move diagonally across the conveyor to gently push the product onto a takeaway line.

- This makes the shoe sorter ideal for sorting a very wide range of product sizes and shapes, including unevenly weighted cartons.

- Takeaway lanes are typically placed at a 30-degree angle, or a 22-degree angle to the main slat conveyor.

- Takeaways at 22 degrees will consume more floor space but provide for higher speed sortation.

- Some shoe sorters can divert to both the left and right, and products do not need to be justified to either side of the sorter at the induction point.

4. Line Sorter

- Line Sorter is a semi automatic sortation solution for small and mid-size parcels.

- The solution may consist of a line camera or sorter devices which are used for registering shipments and a conveyor belt with a sortation mechanic which will deliver the parcels to detachable bags according to the selected sort plan.

5. Slide Tray Sorter

- The slide tray sorter is built to offer a sorting alternative for fragile products or products that can’t be handled by a split tray sorter.

- The products are safely transported on angled trays. At the destination exit, the hatch on the bottom of the tray opens and the product gently slide into the angled chutes.

- This smooth sliding feature makes the system perfect for handling fragile products.