Conveyor System

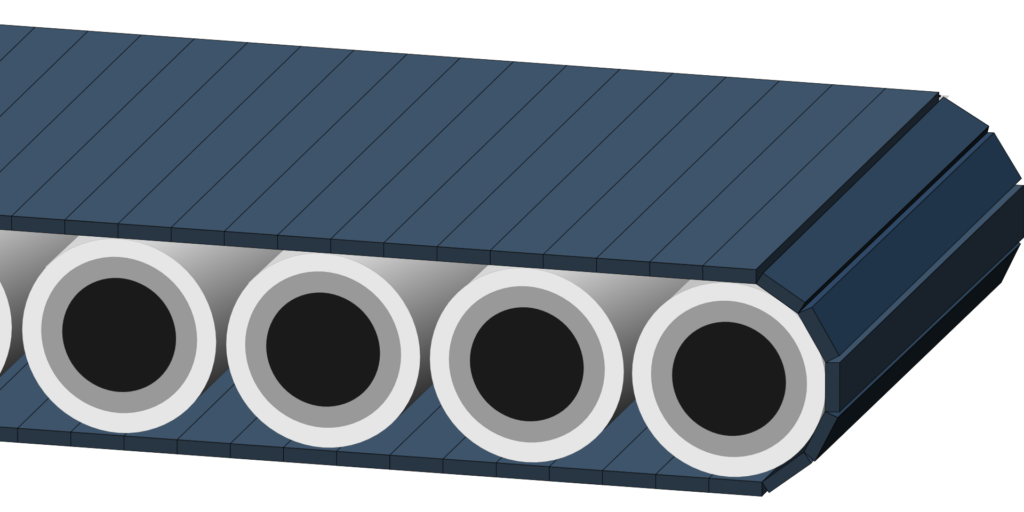

A Conveyor system is a quick and effective mechanical handling mechanism for automatically conveying loads and products within a certain area. Among other advantages, this technology eliminates human error, reduces workplace hazards, and decreases labour expenses. They are handy for moving large or heavy objects from one location to another. A conveyor system may transfer goods using a belt, rollers, or chain.

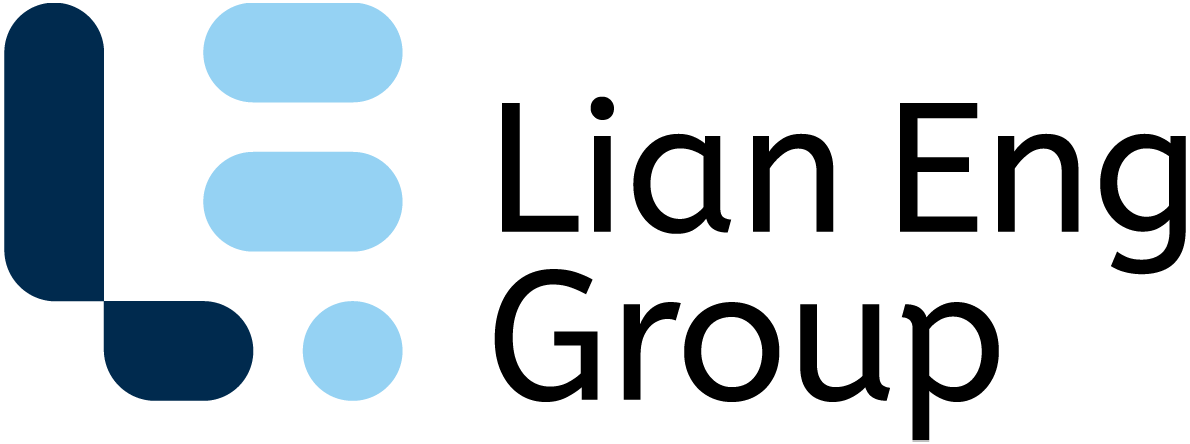

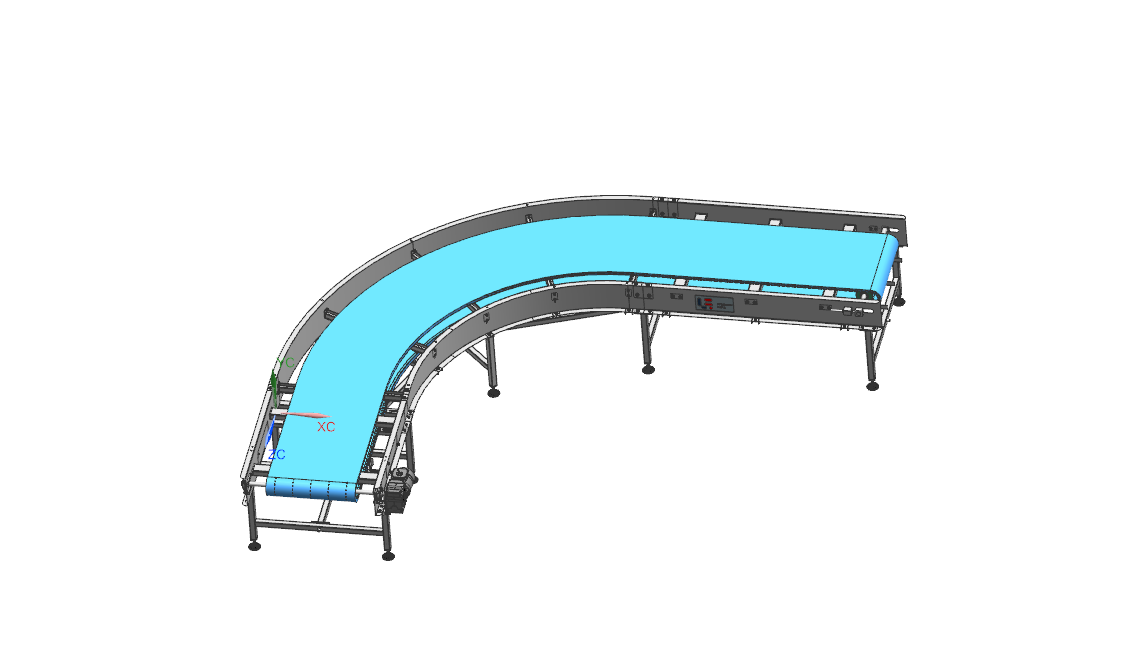

Some of the commonly used conveyors are straight, incline, decline, curve, Z conveyors, These conveyors serve a wide array of purposes, depending on the requirements.

We provide off the shelf, customized or stand-alone units to fit your operation needs. Whether it’s used at food production lines or at a 24/7 FMCG warehouse, the conveyors can be tailor made to suit the current process.

Advantage of conveyor system

A conveyor system’s primary function is to transport things from one area to another. The design permits the transport of goods that are too heavy or bulky for individuals to carry.

When moving objects from one area to another, the conveyor system saves time. As they can be inclined to cover numerous levels, they make it easier to transfer objects throughout multiple floors, a physically demanding process when done by operators. Inclined belts may automatically discharge material, removing the requirement for a person to be present at the receiving end.

Choosing the right conveyor system

A conveyor more or less works as a central system for businesses that receive, handle, store, distribute, produce or transport items.

Selecting the proper conveyor system may be tough for warehouse managers and other stakeholders owing to the various conveyor types and hundreds of different configurations to select from.

In addition, there are a number of elements to consider when identifying and purchasing the ideal conveyor system for your warehouse or distribution center. You should concurrently examine both product and process needs.

First off, an ideal conveyor system must be:

Operationally Safe and energy efficient

Reliable parts and components

Adaptable to changing requirements

cost-effective

Installing the improper conveyor system can swiftly erode a warehouse’s operating effectiveness, leading to increased cost and decreased customer satisfaction, finally depriving the firm of its competitive edge.

Let our team of experienced personnel help you find the best conveyor system for your operation needs.

Why our customers choose us :

- 24-hour service across any location in Singapore.

- On-site service with in-house factory automation specialist and trained personnel in Forbo Siegling Conveyor belt.

- Local Distribution Center for Forbo Siegling belts.

- Local production and manufacture (customized and application specific).

- Diverse range of Factory Automation products (first-class quality, World Class Manufacturers).

- Conveyor Belt Production options up to widths of 5 meters.

- Product development for special customer requests.